In the world of professional ironing and garment finishing, precision and efficiency are critical. Whether it’s in high-end fashion houses, industrial laundry services, or textile manufacturing, delivering wrinkle-free, perfectly pressed garments requires advanced technology. Among the innovative tools shaping the industry, the Small Vacuum Table has emerged as a vital component, redefining the ironing process with its unparalleled precision and versatility.

What Is a Small Vacuum Table?

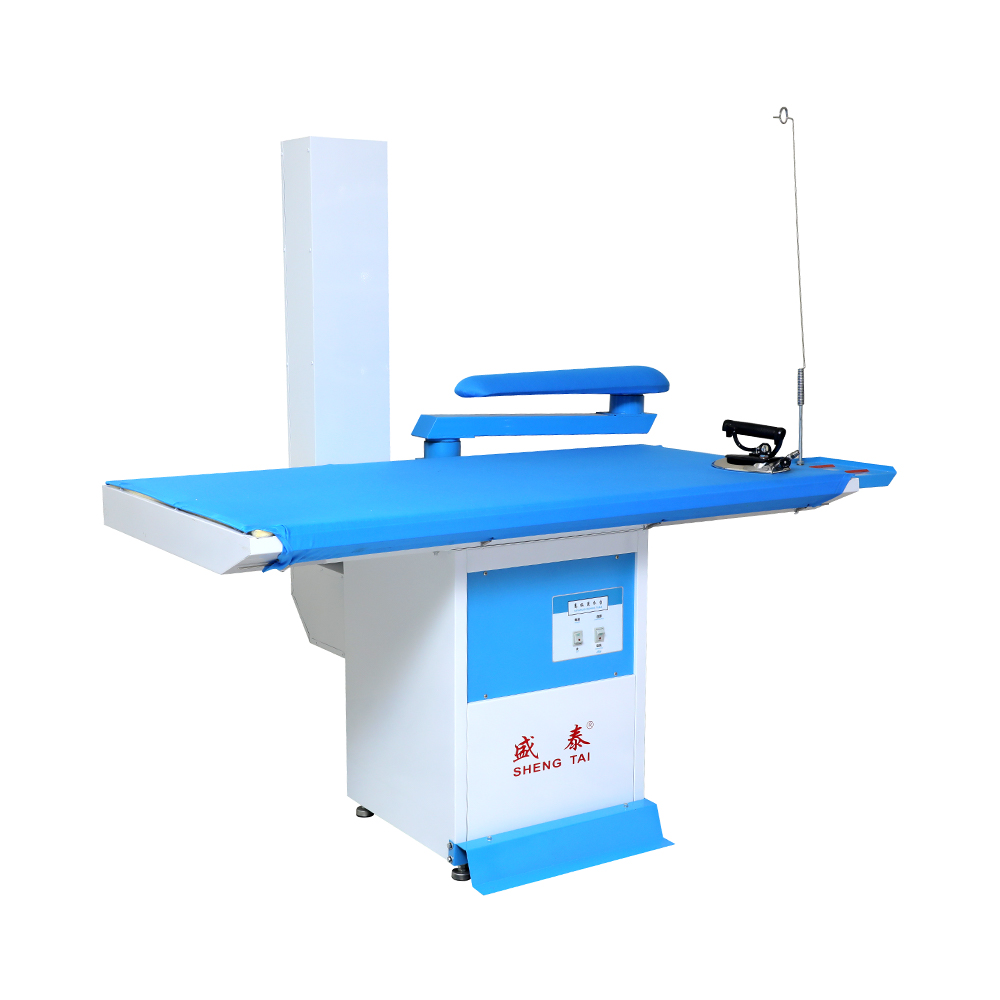

A Small Vacuum Table is a compact, work-holding device designed to provide suction during ironing or pressing processes. It creates a vacuum beneath the fabric, holding it firmly in place while allowing steam to flow through the material. This combination ensures superior wrinkle removal and precise pressing, making it an indispensable tool for professionals in garment care.

These tables are especially valued for their portability and efficiency. Their small size makes them suitable for both boutique operations and large-scale industrial facilities, offering flexibility without compromising performance.

The Importance of Precision in Professional Ironing

Professional ironing isn’t just about removing wrinkles; it’s about achieving a polished, uniform appearance that meets exacting standards. For industries like fashion, hospitality, and textile production, the quality of ironing directly influences customer satisfaction and brand reputation. Achieving this level of precision requires tools that go beyond conventional irons and boards. This is where Small Vacuum Tables excel.

The vacuum function stabilizes fabrics during pressing, preventing shifting or stretching that can compromise the garment’s integrity. Additionally, the suction allows for better steam penetration, ensuring even the most stubborn creases are eliminated without damaging delicate materials.

Advantages of Using Small Vacuum Tables in Ironing

Enhanced Fabric StabilityThe vacuum suction holds fabrics securely, reducing movement during ironing and ensuring consistent results across the entire garment.

Improved Steam PenetrationBy drawing steam through the fabric, Small Vacuum Tables enable deeper and more even heat distribution, which is essential for achieving professional-quality finishes.

Versatility Across FabricsFrom delicate silks to heavy-duty denim, these tables accommodate a wide range of materials, making them suitable for diverse ironing needs.

Compact and Space-Efficient DesignTheir small footprint allows for easy integration into tight workspaces, making them ideal for both small boutiques and large-scale operations.

Increased ProductivityBy streamlining the ironing process and reducing the need for rework, Small Vacuum Tables help professionals handle higher volumes with greater efficiency.

Applications in Different Sectors

The adaptability of Small Vacuum Tables has made them a staple in various industries:

Fashion and Tailoring: Ensuring perfectly pressed garments for runway shows, retail displays, and bespoke tailoring.

Textile Manufacturing: Prepping fabrics for cutting and sewing by removing creases and ensuring uniformity.

Hospitality: Delivering crisp linens and uniforms for hotels and restaurants.

Industrial Laundry Services: Enhancing the efficiency and quality of pressing large volumes of garments.

Innovations in Small Vacuum Table Technology

Recent advancements have made Small Vacuum Tables even more effective and user-friendly. Features such as adjustable suction levels, integrated heating elements, and ergonomic designs have improved both performance and operator comfort. Some tables now include smart controls that monitor temperature and suction in real-time, ensuring optimal settings for different fabrics.

Additionally, manufacturers are incorporating sustainable practices into their designs. Energy-efficient motors and recyclable materials are becoming standard, aligning with the industry’s push toward eco-friendly solutions.

Overcoming Challenges

While Small Vacuum Tables offer significant benefits, they are not without challenges. Proper maintenance is essential to ensure consistent suction and longevity. Regular cleaning of the table surface and filters prevents blockages and maintains performance. Additionally, operators must be trained to use these tables effectively, particularly when working with delicate or unconventional fabrics.

Despite these considerations, the advantages far outweigh the drawbacks, making Small Vacuum Tables a worthwhile investment for any professional ironing operation.